In the previous section we presented a feeding system for additives in a plastics factory with a special program for extrusion blow molding (EBM), such as ColorSave 1000 which is easier for the operator to use than a feeding system with a regular extrusion program, since the EBM program “speaks his language”, i.e. the language of product weight and not the language of extrusion factories in terms of kg/hour of the production line. In addition, we stated that the feeding system with the EBM program works in sync with the production machine and allows the operator to work in a synchronized manner by means of only two values – product weight and desired percentage. We mentioned that the feeder knows the extruder’s momentary throughput via a variable representing the synchronization with the extruder and a constant reference point, and in this section we’ll see why in EBM production lines with feeders equipped with EBM programs it’s easier to carry out the synchronization of the feeder and the production machine and it’s also easier to calculate the reference point.

In the previous section we presented a feeding system for additives in a plastics factory with a special program for extrusion blow molding (EBM), such as ColorSave 1000 which is easier for the operator to use than a feeding system with a regular extrusion program, since the EBM program “speaks his language”, i.e. the language of product weight and not the language of extrusion factories in terms of kg/hour of the production line. In addition, we stated that the feeding system with the EBM program works in sync with the production machine and allows the operator to work in a synchronized manner by means of only two values – product weight and desired percentage. We mentioned that the feeder knows the extruder’s momentary throughput via a variable representing the synchronization with the extruder and a constant reference point, and in this section we’ll see why in EBM production lines with feeders equipped with EBM programs it’s easier to carry out the synchronization of the feeder and the production machine and it’s also easier to calculate the reference point.

In an EBM production line, a feeder with an EBM program has an advantage regarding synchronization with the production machine. A feeder with an extrusion program can be synchronized with the production machine by means of an analog sync signal, usually 0-10V or 4-20mA, which is synchronized in direct proportion with the speed of the extruder’s motor. Sometimes it’s not possible to obtain an analog signal, mostly in old extruders. With these extruders, it’s still possible to send the feeder a sync signal by way of a digital tachometer operated by an encoder installed on the extruder’s motor, but since this entails a somewhat complicated installation and the expense of additional equipment, in most cases of an extruder without an analog output, synchronization is abandoned and the work is carried out with a constant throughput.

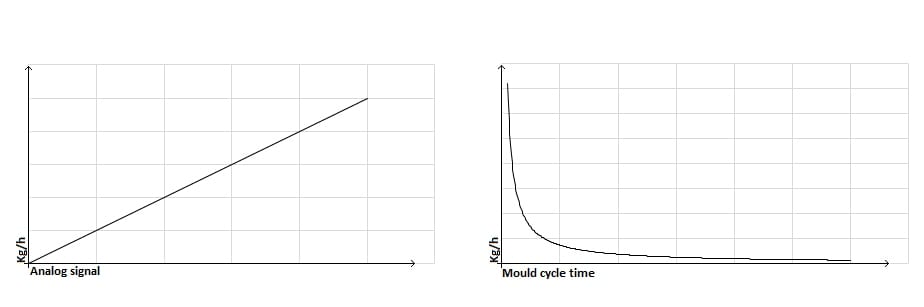

In a feeder with a special program for EBM the synchronization of the production machine and the feeder is made simpler by a digital signal, usually dry contact, that is received from the mold once per cycle. The time lapse between signals is the cycle time. When the weight of the product being made doesn’t change, as the cycle time increases the extruder throughput decreases accordingly and vice-versa. That is to say, the correlation between the cycle time and the throughput is an inverse ratio.

Through the synchronization of the feeder and the mold one can achieve synchronization with the system’s throughput faster and more simply than with synchronization of the extruder and a feeder with an extrusion program.

Illustration: throughput as dependent on an analog signal vs. throughput as dependent on cycle time

Illustration: throughput as dependent on an analog signal vs. throughput as dependent on cycle time

In an extrusion program the reference point is the maximum throughput of the extruder in kg/hour. This is an apparently measurable value, but in practice it’s not simple at all to measure. Even if the maximum actual throughput for a specific material has been measured, the value could be different for different materials and even the same material from different batches might yield a different maximum throughput of the extruder.

In the EBM program the reference point is the product weight, which is a value the operator knows or can easily find out by weighing the final product and adding the weight of the material from that cycle that wasn’t used and is to be recycled. The operator enters the product weight and from that moment, together with the cycle time, the extruder’s throughput can be calculated and synchronization can be carried out. The synchronization will remain stable for every batch of raw material.

We’ve seen that operationally, extrusion blow molding is a sort of hybrid between injection and extrusion. Additive feeders usually have a program for injection and another for extrusion. We’ve presented a dosing system with a program specific to EBM that is preferable from the machine operator’s point of view to a system with an extrusion program because it speaks his language, using terms of product weight as opposed to terms of kg/hour that are foreign to him.

In all matters of synchronization, which is important to the system operator, we’ve seen that a feeder with an EBM program is always in sync with the production machine and that carrying out synchronization is easy, as is the calculation of the reference point for synchronization.

Now it’s easy to understand why EBM operators prefer additive feeders with programs specific to EBM.

Speak directly with our engineers and find ways to reduce cost, inventory and time

Request a Demo© Copyright Ampacet Corporation. All Rights Reserved