Anyone who has ever worked with a multi-cavity mold knows that sometimes there may be a problem in one or more of the cavities, such as a scratch in the cavity, a leaky nozzle, a foreign object in the nozzle tip, etc. In such a case, the right thing to do is to stop and repair the mold. However, in real life that is frequently not an option, since there are customers’ orders that need to be supplied, and there’s no choice but to block the problematic cavities and keep working.

When one or more cavities are blocked, less material is naturally injected into the mold from the injection machine and the shot weight is reduced. It follows that the amount of masterbatch that should be dosed into the mold is also reduced. If one or more cavities are blocked but the amount of masterbatch remains equal to the amount dosed to an entire mold with no blocked cavities, it means that the manufacturer used an excess of masterbatch.

In spite of this, many operators tend to ignore the necessary change in the amount of masterbatch in the event that one or more cavities are blocked. One reason for this is lack of attention, since the operator is preoccupied with many problems. Another reason is that the operator doesn’t consider the change in the required amount of masterbatch to be important. Another reason, and perhaps the main one, is the inconvenience of calculating the new amount of masterbatch that should be dosed. Whatever the reason, the operator used an excessive amount of costly masterbatch, thereby wasting money and at times even damaging the quality of the product.

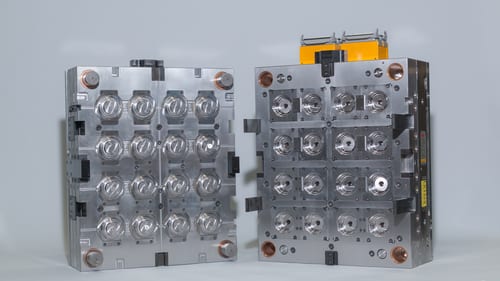

In most gravimetric feeders, the operator has to enter the shot weight and the masterbatch percentage in order for the feeder to calculate how much masterbatch to dose in each cycle. The shot weight of the multi-cavity mold is known to the operator, however when one or more of the cavities are blocked, the shot weight is no longer known and must be calculated. For example, a multi-cavity mold has 16 cavities and the shot weight is 148.8 gr. One of the cavities is blocked and the operator must calculate the new shot weight. The solution is 148.8/16 x 15 = 139.5 gr. It’s not a complicated calculation, but nevertheless it deters many of the operators, who know very well how to operate injection molding machines, but are put off by math.

The most advanced gravimetric feeder, LIAD’s ColorSave 1000, has an elegant solution for the problem. The operator can choose whether or not to work with the feeder’s cavities feature. When working with the ColorSave 1000 with the cavities feature, the operator no longer enters the shot weight, but instead enters the cavity weight and the number of cavities, and the ColorSave 1000 calculates the shot weight by multiplying the two numbers (The cavity weight must include the sprue and at times the runner as well, depending on the mold). When you choose to work with recipes (with the ColorSave 1000 you can choose to work with or without recipes) the cavity weight and the number of cavities are saved in the recipe. However, the operator can choose a number of operational cavities that’s different from the number in the recipe, without changing the recipe.

Many injection factories around the world enjoy this feature and adjust the shot weight automatically by updating the number of cavities in the ColorSave 1000, thus using the desired amount of masterbatch without wasting money and without compromising the quality of the product.

Speak directly with our engineers and find ways to reduce cost, inventory and time

Request a Demo© Copyright Ampacet Corporation. All Rights Reserved